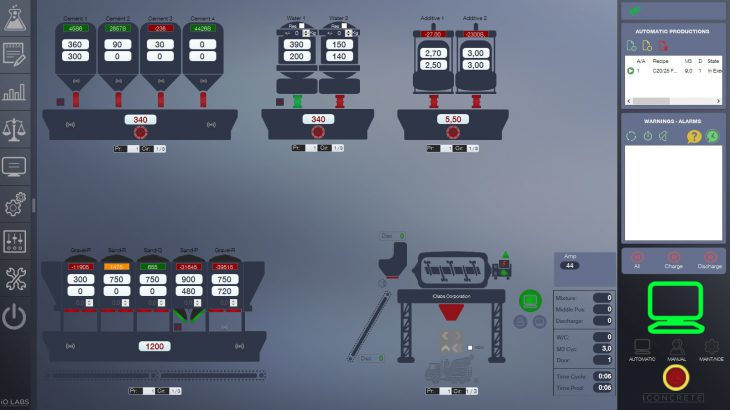

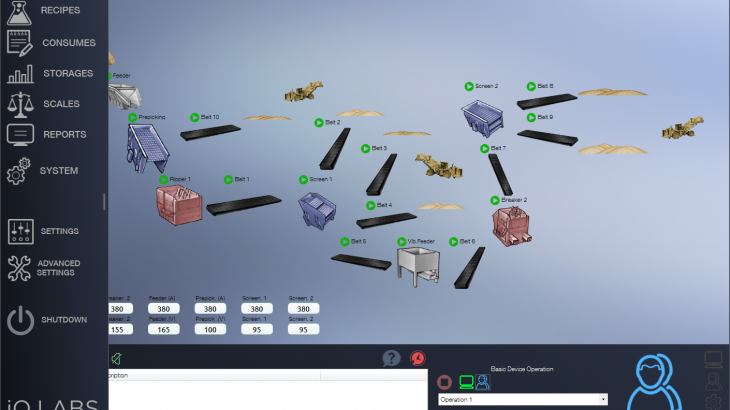

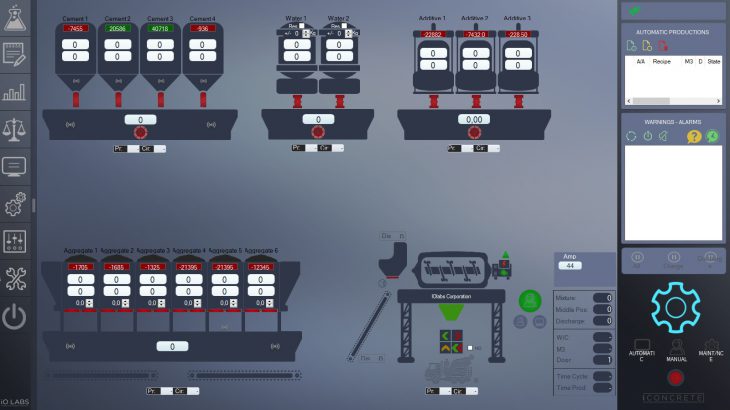

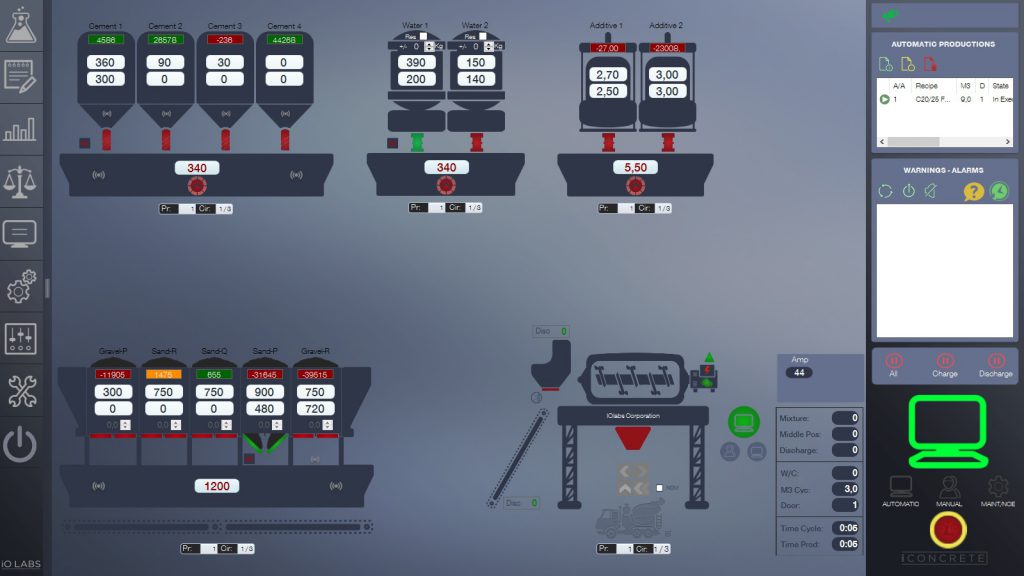

Now iOLABS enables you to download the iConcrete – Concrete Production Automation System Demo and discover all the incredible features it provides at this site: http://iconcrete.eu/iConcreteDemoVersion.exe.

Demo needs a good internet connection, since it is installed in our company’s cloud, and is fully functional.

Indicatively, some of the companies that use our Automation are:

- LARSINOS SA

- DOMIKA PASISI SA

- NIKOS V.L.T.

- KOUNENAKIS BROS SA

- TEVAR SA

- IONIOS BETON.

- SYNERGATIKI BETON.

- TECHNOBETON SA

- POLITI BROS SA

- NEVISO LTD.

- AGIKONS S.A.

You can also watch video in our automation mode at http://iconcrete.eu, at our company website, and at IOLABS’s Social Media (facebook, LinkedIn, twitter )