IOLABS Automation & Software Technologies, completed in record time the complete reconstruction of a mobile Asphalt plant for the company TEVAR SA. The reconstruction included restoration and upgrading of the mechanical equipment and installation of the new automation of our company iAsphalt.

With these changes we managed to create a fully mobile asphalt plant, reducing the installation & ready-to-work time to just 1-2 days. These tasks included:

Aggregates dosing:

- Installation of a separate dosing system controlled by inverters by installing new motors and reducers.

- Installation of Stability system with legs and shaft repair.

- Capacity expansion with construction of railings.

- Installation of vibrators in aggregate storages.

- Conveyor belt repair and replacement of belts & rollers on the conveyors.

Aggregate Preparation – Filters:

- Installation of automatic drum ignition control unit.

- Installation of fuel oil and circulation system & injection system by installing fuel transfer pumps & control injection pumps and fuel injection control unit.

- Fuel heater repair and installation of safety terminals.

- Installation of fuel and material temperature monitoring thermometers.

- Drum & material lifter motors & reducers repair / replacement .

- Hydrocyclone Repair.

- Repair of hydrocyclone pump and filter system motors / reducers.

- Reconstruction of air ducts.

Asphalt Preparation:

- Installation of Asphalt Tank Burners.

- Installation of safety terminals and asphalt temperature monitoring sensors.

- Installation of oil-heated double-walled asphalt supply network.

- Tank Repair.

Aggregate Separation, Dosage & Mixing:

- Material separation sieve repair.

- Oil heater repair with resistors.

- Construction and installation of oil heated Asphalt Scale.

- Repair / Replacement of hot Aggregates storages and dosing system.

- Installation of Aggregates, asphalt and oil circuit temperature sensors.

- Air system installation.

- Asphalt mixer repair.

Electrical & Automation Works:

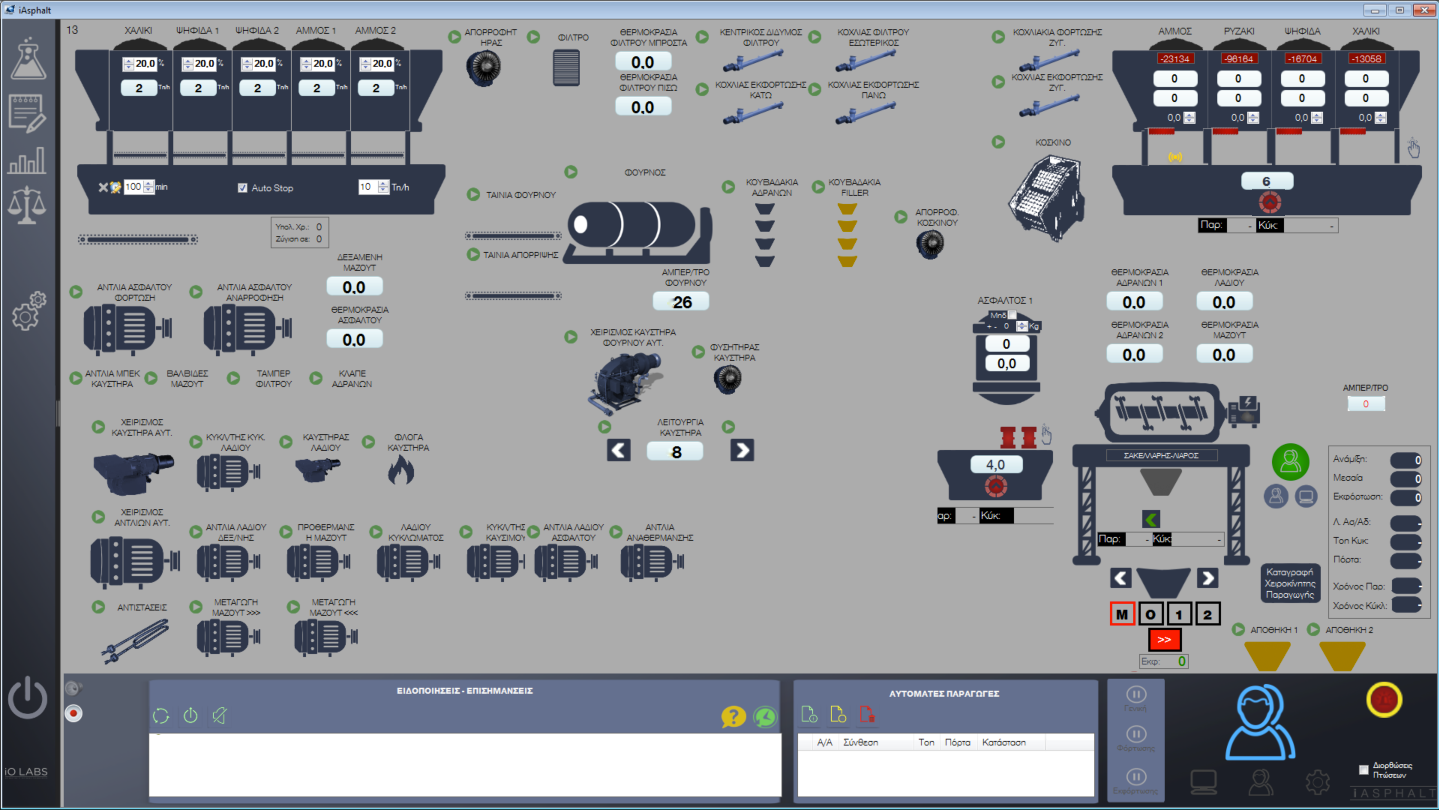

- Installation of iAsphalt asphalt automation system.

- Wiring of the entire asphalt complex with Plug & Play capability for all the individual components of the machine.

- Repair and upgrade of electrical panel with automatic switching system.

- Lighting installation throughout the plant.

- Installation of a camera system for better control of the operation of the machine.

- Electrical installation on control room.

Everyone at iOLABS Automation & Software Technologies would like to thank all our partners & staff for completing this project in record time !!!