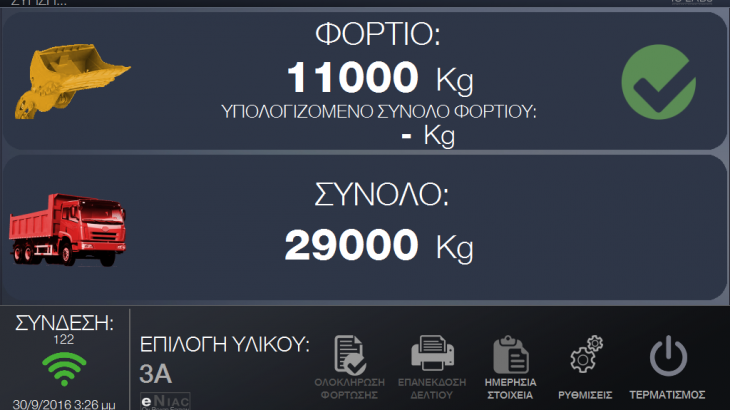

eNiac is a new on board weighing system for wheel loaders from iOlabs Automation & Software Technologies.

It uses the state of art oil pressure sensors and position control sensors and new sophisticated weighing techniques and sampling management and thus can achieve high-precision weighing in no time.

eNiac comes with a new, modern graphical UI and wireless connection thus providing ease of use and ability to connect it in any accounting package for the issuance of delivery notes.

Adaptable to any Wheel Loader type: By using weighing algorithms that support the use of one or more oil pressure sensors and the control unit that supports thousands of samples per second, eNiac can easily be installed on any type of loader.

Installation in just a few hours: Installing eNiac on any type of wheel loader can take 2-3 hours including sensor installations, weighing calibration and system setup.

eNiac Central Unit: Capitalizing years of experience of its Technical Department, iOlabs created the eNiac CPU and its Operating System to be able to manage thousands of samples per second and provide maximum weighing precision.

Signal normalization system: Using filtering circuits, and sophisticated algorithms, eNiac achieves absolutely accurate weighing.

Weighing Settings: All settings like weighing acceptance time and time to reweigh, are directly accessible by the user and can be modified in order to adjust eNiac to the way of working he prefers.

Last bucket weighing Removal: Even if the user has configured the system to instantly record the weighing values, eNiac enables correct weighing, with the removal of the last bucket weighing, so you can just recalculate the demanded material quantity.

Material Management: Through a list of all materials that can be loaded by the wheel loader, eNiac allows operator to change easily and quickly the material to be loaded and will be referred to the weighing log.

Reissue Weighing Logs: eNiac allows user to easily reprint Weighing Logs from previous loading.

Direct Weighing Logs Printing: By using thermal printers, the operator can immediately after loading, print weighing logs as well as all relevant information such as date and time, material and total load.